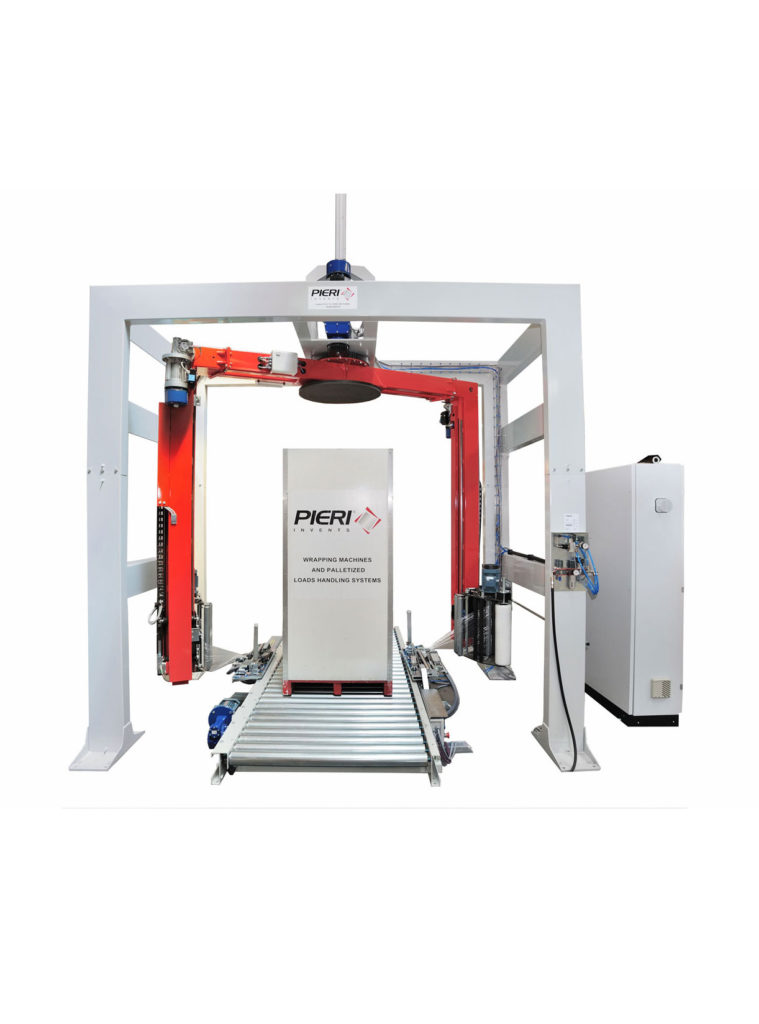

SILVER TWIN, the twin rotating arm wrapping machine by Pieri, is the ideal solution for customers who demand the best from their machines: high speed and productivity.

SILVER TWIN is a high-efficiency machine whose design features make it exceptionally solid and reliable.

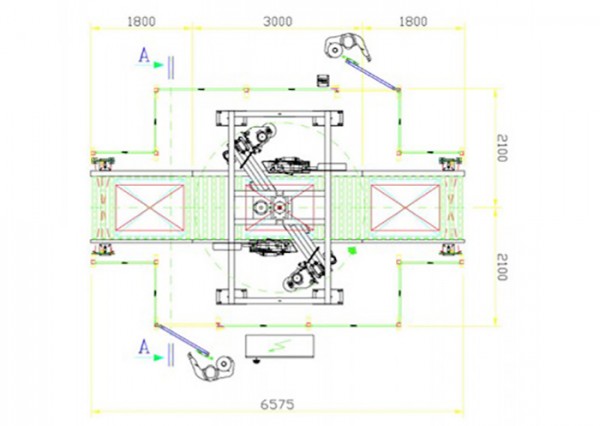

It has a strong steel structure with four supports which guarantee stability in the points where it comes under the most stress.

The standard SILVER TWIN model features:

- 2 motorised pre-stretch carriages (model MS-Pro) controlled by an inverter, with pre-stretch with fixed interchangeable ratios. The speed with which the film unwinds is controlled by a sensor which constantly adjusts the motor speed to ensure the pressure exerted on the film is the same over the whole perimeter of the load. The force exerted by the film on the product is electronically controlled and adjusted from the electrical control panel.

- 2 cutting and welding units which cut and weld the stretch film after wrapping. This prevents loose film tails which could cause load stability problems during transportation. This clamping system can be used with any kind of load; the welding unit never comes into contact with the product as it operates against a contrast bar that is then folded away.