Modelli UNICA CAD

Models UNICA CAD

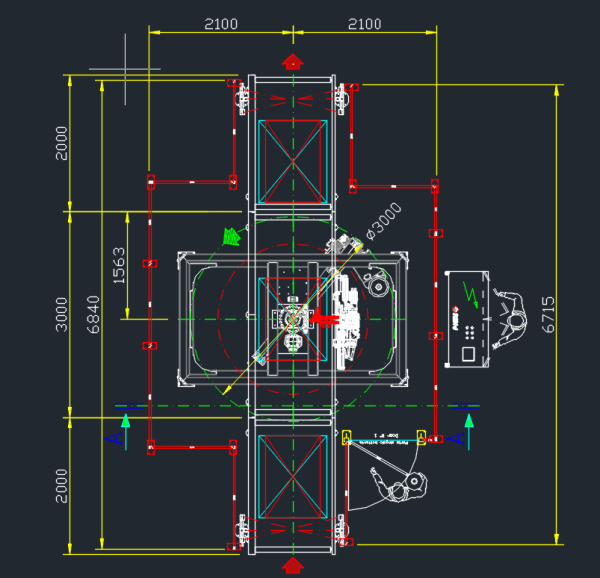

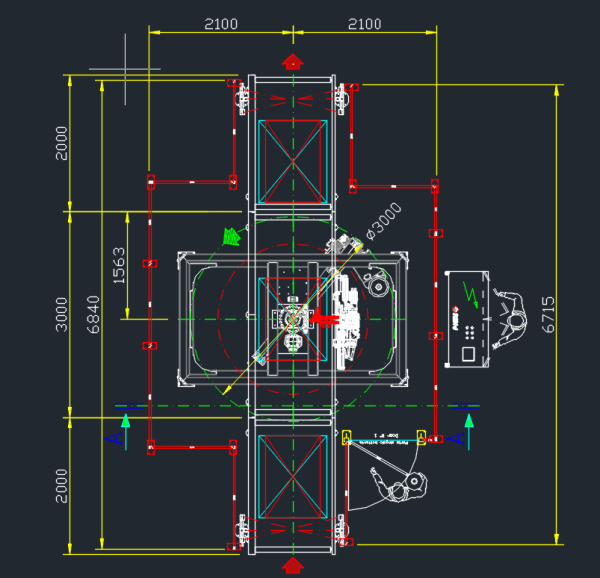

Layout

Gallery

Ricevi subito via email la brochure di UNICA CAD

Compila il form sottostante per ricevere la brochure via email.

Request the UNICA CAD brochure, now

Fill the underlying form to receive it.

Modelli UNICA CAD

Models UNICA CAD

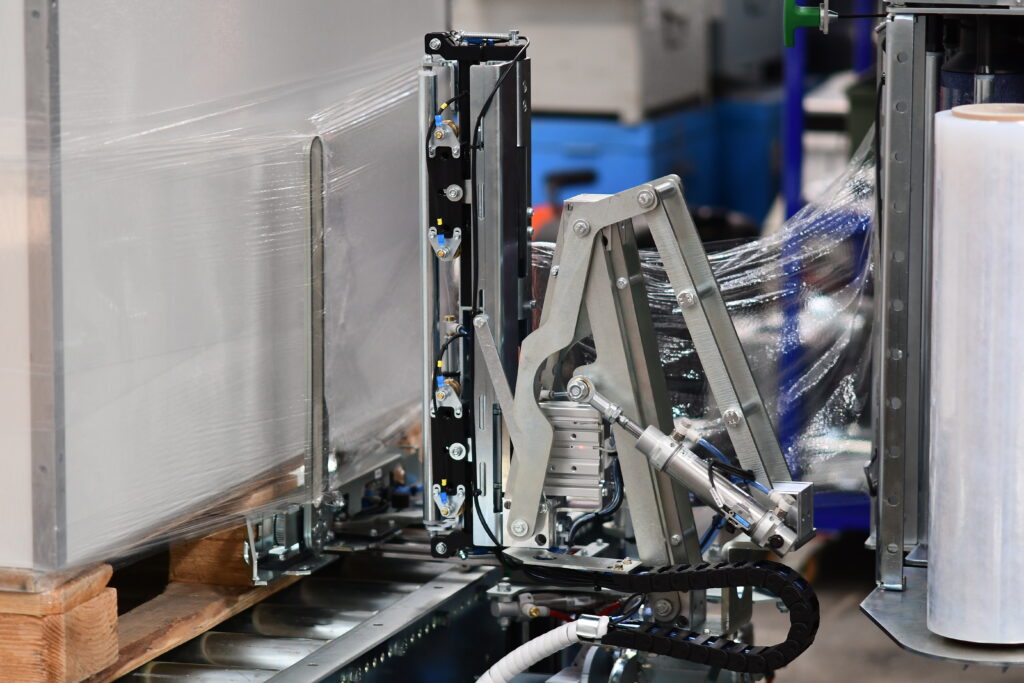

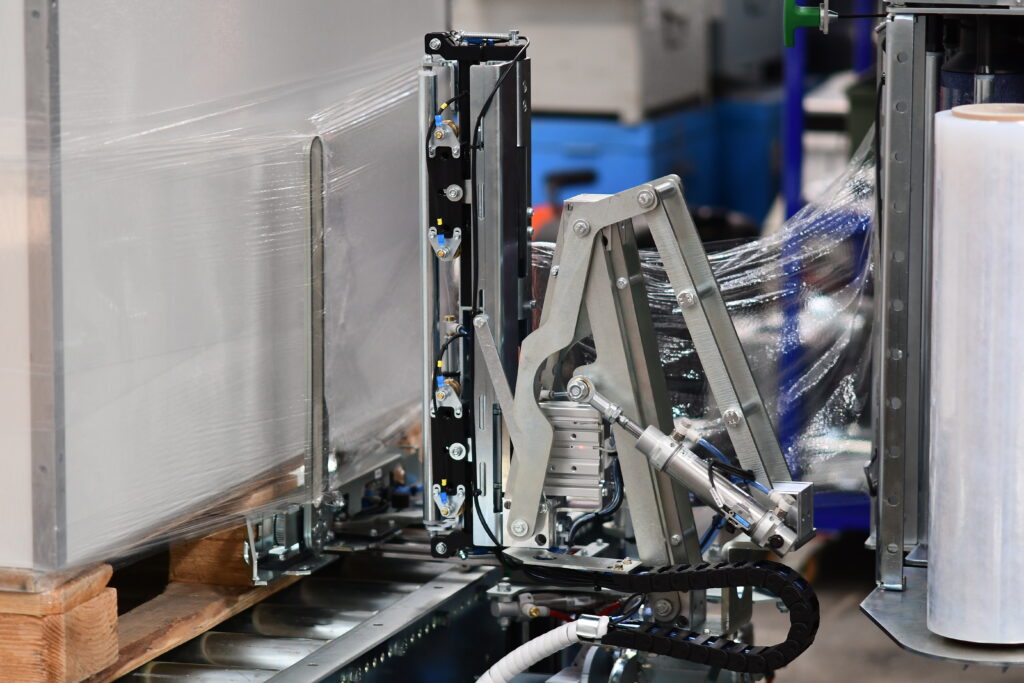

UNICA CAD, thanks to the automatic device integrated into the machine frame, allows for additional load protection by applying cardboard corner protectors to the edges of the product to be wrapped.

UNICA is the line of automatic rotary arm machines for packaging palletized loads with stretch film: the latest addition to the PIERI family. The machine boasts 5 innovative patents that offer customers numerous new technologies and applications. Thanks to its high level of customization, the machine can be adapted to meet each customer’s specific needs, ensuring a stable and durable solution.

The high-strength shaped structure structure provides high strength, setting it apart from the typical structural design of classic arm machines. The machine guarantees load stabilization, allowing for high adaptability when it comes to the products to be packaged.

It is also equipped with an advanced single-motor TPS prestretch carriage, which is used to adjust the tension and dispensing speed of the stretch film. With the absence of a dandy roller, wear is minimized, resulting in a longer-lasting and more effective machine.

The machine also features an important innovation regarding film insertion: the quick film insertion (Q.F.I) allows for a simplified insertion of the stretch film into the prestretch carriage, making it much more efficient and faster in terms of time and resource utilization.

CONTACTLESS SYSTEM: The stretch film cutting is performed using a contactless hot wire. Thanks to this technology, the cutting occurs without contact, and the wrapping process ensures higher efficiency, precision, and reduces the need for maintenance.

Due to its reduced footprint for installation, the machine can be easily adapted to any type of layout.

UNICA allows for the integration of a top sheet to provide additional protection from water or dust, ensuring 100% safety for the packaged product, both for storage and transportation.

UNICA represents the ideal solution to meet your end-of-line needs.

UNICA CAD Productivity: 26 RPM

| STANDARD MACHINE SPECIFICATIONS | ||

| Min. pallet dimensions (LxW) | 400x600 mm | |

| Max. pallet dimensions (LxW) | 1120x1420 mm | |

| STD pallet height | 2100 mm | |

| Stretch film reel D. | 250 mm | |

| Film reel | 18 Kg (OTHER ON REQUEST) | |

| Conveyor height | 500 mm | |

| Stretch film reel height (mm) | 500 mm | |

| Max. reel external diameter (mm) | 250 mm (OTHER ON REQUEST) | |

| Film reel weight (Kg) | 18 Kg (OTHER ON REQUEST) | |

| Film Tickness (Q) | 10-35 micron | |

| UNICA CAD | UP TO 26 RPM | |

The top press plate exerts pressure on the palletised load to keep it stable during wrapping.

Specially designed for wrapping machine loads, it is available in a pneumatic or electromechanical pantograph version.

This device lifts the pallet during wrapping cycle, in this way the film covers both: the load and part or all of the wooden pallet.

As the name suggests, the roping system on the carriage reduces the width of the film until a rope is created, increasing load stability and securing the product to the pallet.

This automatic device, positioned before the wrapping machine, covers the top of the palletised load with a polyethylene film, protecting it from dust. The film is cold cut by a pneumatically powered blade. The amount of film to place on the load is automatically calculated by a photocell, ensuring optimal consumption.

The motorized electronic reel carriage can boast 2 inverter-controlled motors with variable pre-stretching, the percentage can be varied from the control panel (minimum 0% – maximum 400%) and is obtained by acting separately on the speeds of the motors mounted on the carriage. This feature makes it possible to fully exploit the potential of the film used, enabling

Compila il form sottostante per ricevere la brochure via email.

Fill the underlying form to receive it.