Pallet Wrapping Machine: Types, Features and Buyer’s Guide

The automatic pallet wrapping machine is a machine designed for the automatic packing of palletized loads. The purpose of these machines is to protect and stabilize the goods on the pallets that will be shipped or storaged. The protection and the stabilization of the palletized loads is provided by the stretch film, which secures the goods on the pallets. In the next chapter, we will examine the macro-types of wrappers: automatic and semi-automatic (or manual).

Automatic pallet wrapping machine VS Semi-automatic pallet wrapping machine (or Manual)

To further clarify the difference between the 2 types of pallet stretch wrappers, let’s start by comparing: automatic pallet wrapping machines and manual pallet stretch wrappers. The first point we want to consider is that purchasing an automatic pallet wrapper will bring benefits to you and it will drastically increase the productivity of your organization.

Lower labor costs, combined with less film waste and better safety are the main reasons for you to consider an automatic pallet wrapper instead of manual or semi-automatic ones. Many companies that own a manual pallet wrapper don’t know that there have been advancements in their safety systems that can make them more reliable, which is the first reason why they should upgrade their machinery and purchase an automatic pallet wrapper.

Some manual pallet wrappers have exposed wires or motors that could injure someone. Most modern pallet stretch wrappers, on the other hand, are very safe. Another advantage of having an automatic pallet wrapper is the pre-stretching function, which is missing in the classic manual pallet wrapper.

It allows you to pre-stretch the wrapping film, which allows you to use less film; if you manually wrap 100 pallets with a roll of film, with an automatic pallet wrapper it will be possible to wrap 200 to 300 pallets. This saving of money can allow financial resources to be allocated to other company projects. Pieri’s product that implements the pre-stretching function is PEM-DUO, an electronic pre-stretch carriage with 2 motors controlled by inverter with variable pre-stretching.

The pre-stretching percentage can be varied from the electric panel (minimum 120% – maximum 500%), and is obtained by acting separately on the speeds of the motors mounted on the carriage. This feature makes it possible to exploit the characteristics of the film used to the maximum, allowing a considerable reduction in film consumption. Furthermore, the possibility of setting different pre-stretching percentage values for each program and for each phase of the wrapping cycle maximizes performance in terms of pallet load stability.

In addition to this, every company can use the automatic winder to reduce its labour costs: a manual pallet wrapper in fact requires numerous operators to be fully operational. By purchasing an automatic pallet stretch wrapper, you have the opportunity to save on labor costs since automation will take place independently, allowing operators to be assigned to activities that require more critical thinking.

Automatic Pallet Wrapping Machine for protection of the loads

An automatic pallet wrapping machine helps you pack packages, boxes and containers that need to be stored and then transported to their destination. The packaging of your products automatically wrapped by stretch film will have the following features:

- Protected from damage, dust and moisture: using an automatic pallet wrapper will ensure your goods are protected from damage by dirt, dust and moisture.

- Safer: an automatic pallet wrapper will keep the operator on the forklift which is a safety measure. In fact, according to some surveys, it seems that 20% of all accidents involve people walking on the warehouse floor.

- No wear and tear: manual pallet wrapping causes wear and tear injuries while automatic pallet wrapping allows you to protect your employees.

In addition you will be able to:

- Obtain a more efficient wrapping of the product: a manual pallet wrapper does not allow you to guarantee uniformity to the packaging. In fact, there are normally variations in the stretch and efficiency of the packaging such as to obtain an approximate packaging.

- Time saved: with the automatic pallet wrapping machine the packaging will be carried out with a considerable saving of time since you can count on a fast and reliable machine, able to speed up the packaging process drastically;

The manual pallet wrapper, on the other hand, will bring tedious, repetitive and time-consuming work to your operator.

Deepening: Semi-automatic pallet wrapping machine

We have decided to leave this type of pallet wrapper for last as it is a hybrid of the first two, which, being more iconic, deserved a greater comparison and in-depth analysis. Semi-automatic pallet stretch wrappers automatically wrap the load. The “manual” phase, on the other hand, is when the operator has to position the pallet in the wrapping area, hook the first strip of film and start the wrapping process. At the end of the wrapping process, the operator must cut the film and remove the wrapped pallet. It is recommended to purchase a semi-automatic wrapper only if you do not produce more than 20 pallets per hour. The wrapping process is automatic, but the loading and unloading part is not only time-consuming but also dangerous for the operator.

FAQ: common doubts in choosing the right automatic pallet wrapping machine

This chapter has been written together with our technicians and salesmen, as it consists of a guide for the purchase of the right winder for you, structured through the 12 most frequent questions we are asked in the pre-sale phases. Browse through the following questions, identify the ones most in line with your “stomach ache” and consult the answers below.

1. I would like to automate my end of line but I don’t have a palletizer. How can I do it?

Automation of the end of the line is an important choice that can be unrelated to the presence or absence of a palletizer in your company. Pieri is able to propose stand-alone pallet handling and wrapping solutions, independent and not connected to any line. They are easy to use (e.g. with fully automatic cycle) and versatile (by means of transpallet or forklift loading). Click here to discover our offers.

2. I have limited space in my facility, what solution do you have for me?

In 40 years of experience in the packaging sector, we have learned to put our customers’ needs at the center of our activities, so much so that today we always develop our machines starting from their needs. This is what happened with Easy Round, the most compact and versatile machine in our range. Quick to install, easy to use and ready to work in confined spaces. Find out more about Easy Round by clicking here.

3. I only work with hand and electric pallet trucks, is there an automatic solution?

Pieri has solved this need with a solution designed and developed expressly for you: a complete line with ground handling (80mm from the floor). Thanks to it, your operator will comfortably load and unload with the transpallet without any additional device, in total safety and with the performance of an automatic line. Do you want to find out which solution it is? Contact us to find out.

4. My wrap product is particularly large/high, do you have a template for me?

Customizing means studying and solving your peculiarities, in terms of performance and more. Pieri will build the most suitable solution for you. Our experience at your service, this is the added value of Pieri. Are you looking for a customized solution? Click here to be contacted by one of our technicians.

5.How can I protect my operators with an automatic line?

Pieri has always been committed to finding innovative and effective solutions to ensure the safety and protection of your operators. Sensors, photocells, photoelectric barriers, safety interlocks or laser scanners; for Pieri every means and technology are at the service of your safety.

6. How can I save money on my annual film consumption?

If you haven’t read it, know that protecting and stabilizing your product is our goal and our wrapping machines are the solution to this need. However, your investment does not end with the purchase of a line: in 15 years, 90% of the TCO (total cost of ownership) is represented by the consumption of pre-stretch film! You can significantly reduce these costs by choosing the Pieri PEM Duo electronic pre-stretching trolley. By means of it, you reduce the quantity of film while maintaining the efficiency of the wrapping cycle, you protect your product and save on film consumption. Discover more about Pieri PEM Duo, by clicking here.

7. My automated warehouse will not accept pallets with a film queue, what device can I use? And what alternatives do I have to the old system of heat sealing the film?

The problem of the film tail is as old as the wrapping machines, that’s why Pieri has solved and closed the issue for years with the threading gripper ecoMATRIX. It is the effective answer to the film tail as it allows the closure of the winding cycle without the use of sealing devices. To learn more about the ecoMATRIX clamp unit, click here.

8. Can I also protect the top of my palletized product?

Pieri’s lines guarantee stability and protection to your product, including top cover functionality. In fact, the Top Cover device also places the film on the upper part of the product, allowing the dustproof or watertight cycle. We take care of your pallets and protect them from external agents. The answer to your delicate product is the Pieri Top Cover with anti-dust and/or waterproof cycle.

9. I need caregiver service present and constant.

Maintenance is a fundamental part of the life of a winding line. In order to guarantee answers and solutions to your requests for assistance and maintenance, Pieri offers its customers a help-desk with trained and expert technical staff. Our technicians respond in 4 languages and can be reached by phone, email or Skype. Contact Pieri’s technical staff with confidence for any doubt or for an upgrade of your line, through this link.

10. I need to remotely monitor the performance of my line, is it possible to do this?

More and more often our customers need to monitor machine and line performance. Efficiency is not a value written on a piece of paper but the result of the daily work of the machines installed in your company, data and numbers to be checked and managed periodically. The Pieri wrapping machine allows you to remotely monitor the status of the machine, its performance, working hours and pallets wrapped. Pieri sends periodical reports on the operation and performance of the machine. Numbers speak for us, entrusted to those who make efficiency their primary objective.

11. I have different types of products and pallets, how do I get the best protection for each product?

The Pieri wrapping machine allows to create programs with recipes dedicated to the different types of pallets that the customer can use. Each program can be selected from the operator panel and can be customized according to the customer’s needs:

- pre-stretch and film pull adaptable to the various types of pallets,

- variable number of windings in the lower or upper part of the pallet,

- inclusion or exclusion of the various machine options.

12. I need to automate pallet flows within my plant and make these operations more efficient.

Pieri has always worked on the continuous research of innovative solutions to satisfy the customer’s needs in the wrapping and handling part. Our target is to offer “turnkey” solutions that optimize the flow of pallets inside the plant. We study customized end-of-line solutions adapted to the customer’s requirements, through the use of shuttles to transport empty pallets or palletized loads, automatic stackers able to optimize the space in the warehouses, handling able to automate the end-of-line process. Click here to contact one of our technicians and find out more about our automation solutions.

Types of automatic pallet wrappers

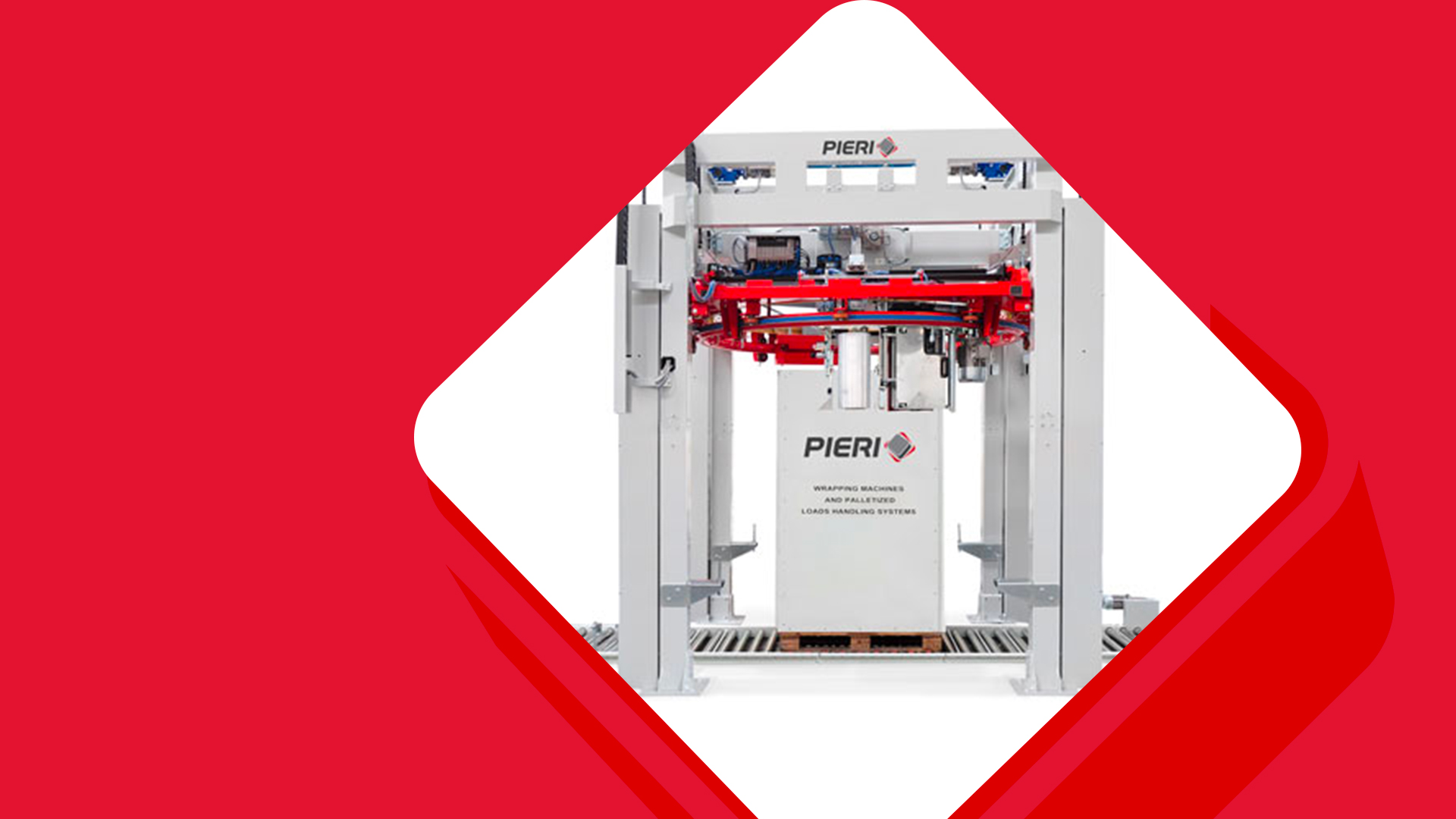

Ring Wrapping Machines

Rotating ring pallet wrappers differ from the other types in that the pallet remains immobile on the wrapping area, while the stretch film is rolled up on the pallet itself through a ring that surrounds it and wraps it up to its full height. With these machines it is also possible to carry out wrapping operations that differ from the traditional ones:

- wrapping only the base of the pallet and the upper part;

- wrapping two entire pallets on top of each other.

Below is a video that shows you how our ring wrappers work.

Click here to discover our ring wrapping machines.

Arm Wrapping Machines

With the rotating arm stretch wrappers the wrapping system remains the same as the previous one; the only differentiating factor is that instead of the ring there is an arm that effectively wraps the pallet. Here too we propose a video that summarizes the functioning of Pieri’s rotating arm stretch wrappers.

Click here to discover our arm wrapping machines.

Turntable wrapping machines

With turntable pallet wrappers, the pallet is placed directly on the turntable. Then the film is wrapped around the pallet by the pre-stretching carriage that runs along a column, while the platform rotates the pallet. Here is the illustrative video that shows you in more detail the features and operation of our turntable pallet wrapper:

They say about us

The Pieri company was founded in 1970 by a promising project of Sauro Pieri, and growing steadily every year, it came to celebrate its 40th year just last year. Born as a local business near Cesena, Pieri has grown so much that it has exported its products abroad. In fact, it’s no coincidence that important newspapers also have them, which we’ll look at below.

Pieri is on “Sole 24 Ore

The main topic of the magazine is the electronic pre-stretching exploited through the Pieri PEM-DUO product. PEM-DUO, as previously mentioned, is a motorized variable pre-stretching trolley. The pre-stretching percentage can be varied in relation to the electrical panel (minimum 120% – maximum 450%), and is obtained by modifying the speed of the motors installed on the trolley. This makes it possible to customize the winding for each type of load, leading to an evident saving in stretch film. Moreover, since this machinery can customize the wrapping for any type of product, it substantially increases the stability of the pallet and therefore decreases the risk of damaged products. The importance of this product has gained national resonance, leading many companies to adopt it in their storage processes. The consequence of this was the ad hoc article on the “Sole 24 Ore”. Here the article.

Pieri and Siemens reference

We have been collaborating with Siemens, a multinational company operating in the automation, electrification and digitalization sectors, for a few years now. Siemens periodically publishes a magazine on digital transformation in various sectors, and this year decided to dedicate an article on Pieri. After an introduction on the history and mission of the business, the article proceeds describing Pieri products, focusing in particular on AVR 400 FLEXA, an automatic ring winder that integrates with the Siemens platform thanks to the PROFINET network. To learn more about the article, click below: https://www.pieri.it/en/pieri-excellence-in-end-of-line-solution-also-according-to-siemens

Pieri – Much more than a company

Pieri is much more than a company for the design and production of highly customized lines for wrapping and handling loads on pallets; it is a company that aims to accompany its customers in the process of warehouse modernization: it educates through customized solutions and training, in order to make the storage phase of companies more effective. Do you want to gather more information about Pieri? Click here and fill in the form: you will be contacted by one of our technicians.